Release of our first CSR Report!

We’re excited to announce the publication of our first CSR Report!

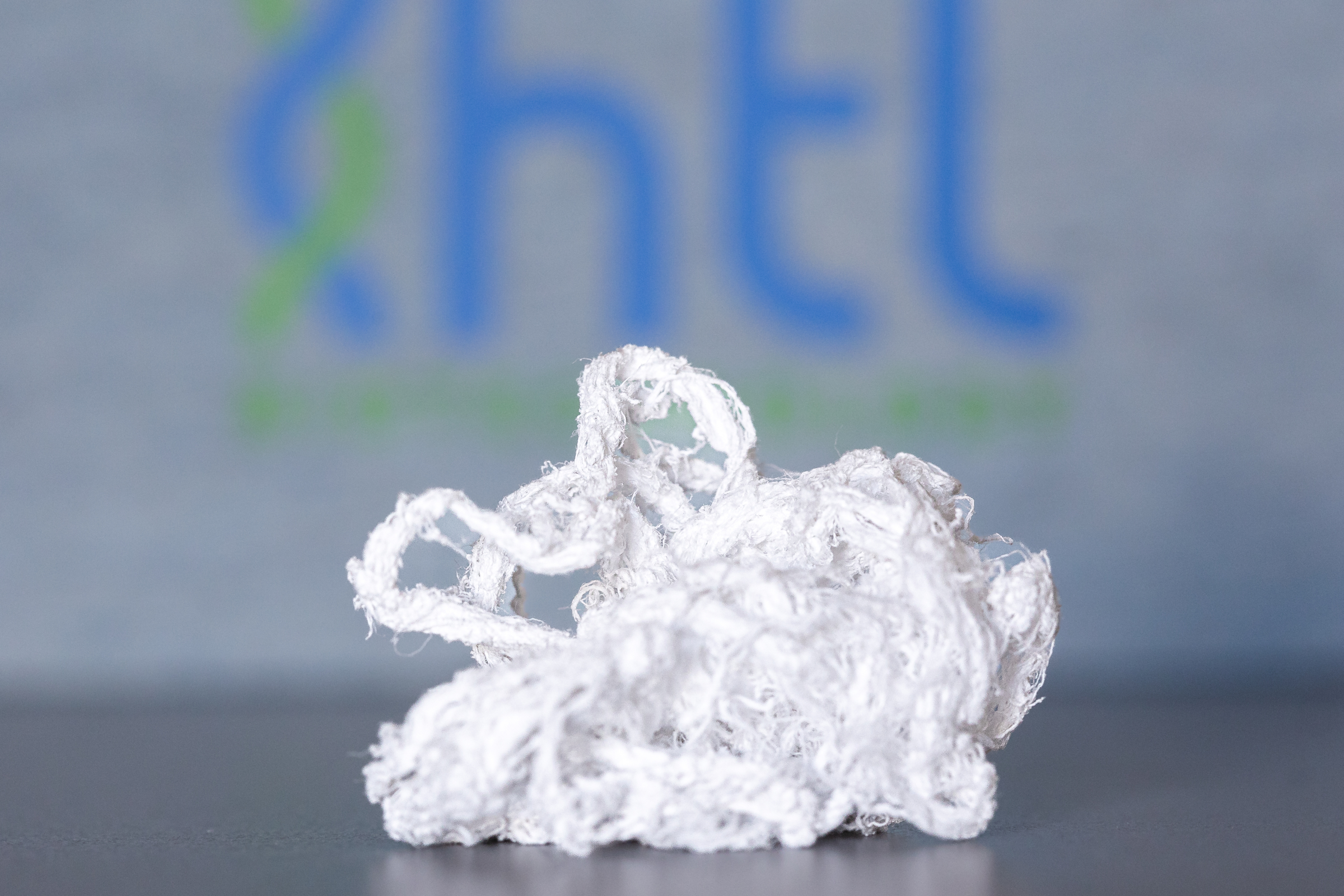

HTL Biotechnology is a french manufacturer of pharmaceutical grade Hyaluronic Acid (Sodium Hyaluronate). Our natural origin HA has been recognized on the market for its premium quality. Our wide range of molecular weight and flexible supply support the evolving needs of the medical devices and pharmaceutical industries.

Features

Advantages

Applications

OPHTHALMOLOGY

Cataract surgery

Dry eye

AESTHETICS

Dermal filler

Skin rejuvenation

DERMATOLOGY

Wound healing

RHEUMATOLOGY

Visco-supplementation

DRUG DELIVERY

REGENERATIVE MEDECINE